PE PP Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,PA POM Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

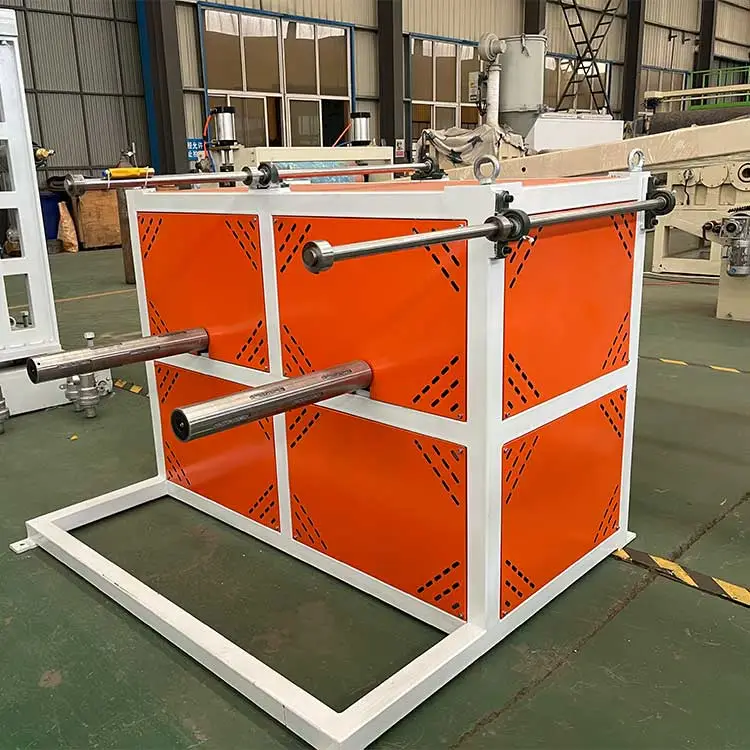

In today’s competitive market, efficiency and durability in manufacturing are not just advantages—they are necessities. The PVC Door Curtain Extrusion Machine from Qingdao Eaststar Plastic Machinery Co., Ltd. stands as a benchmark in innovation and reliability. Designed for producing high-quality PVC door curtains, this machine ensures your operations run smoothly, delivering consistent results that meet international standards. Whether you're enhancing existing production lines or starting a new venture, this equipment offers the precision and performance needed to excel.

Imagine a scenario where downtime and material waste plague your production process. Traditional machines often struggle with maintaining uniform thickness and smooth finishes, leading to rejected batches and lost revenue. With our extrusion machine, these challenges become a thing of the past. Its advanced control systems and robust construction minimize errors, allowing you to focus on scaling your business. The integration of cutting-edge technology means you can achieve superior output with minimal manual intervention, making it ideal for both large-scale manufacturers and growing enterprises.

What makes the PVC Door Curtain Extrusion Machine a top choice? First, its construction utilizes high-grade materials resistant to wear and corrosion, ensuring longevity even in demanding environments. The intelligent design incorporates user-friendly interfaces, reducing the learning curve for operators. Additionally, Qingdao Eaststar Plastic Machinery Co., Ltd. backs each unit with comprehensive quality assurances, including warranties and dedicated technical support. This commitment to excellence translates into peace of mind for our clients, knowing they have a partner invested in their success.

For businesses targeting sectors like agriculture, warehousing, or retail, PVC door curtains are essential for temperature control, pest prevention, and energy savings. Our machine enables the production of curtains that are not only functional but also customizable in terms of color, transparency, and thickness. This versatility opens doors to diverse market opportunities, helping you cater to specific client needs without compromising on quality.

To address common production hurdles, we’ve engineered solutions embedded in the machine’s parameters. For instance, inconsistent output speeds can disrupt workflow. Our model features adjustable extrusion rates and temperature controls to maintain uniformity. Below is a detailed table highlighting key specifications:

| Parameter | Value | Benefit |

|---|---|---|

| Extrusion Output | Up to 150 kg/h | High efficiency for mass production |

| Screw Diameter | 65 mm | Optimal material processing and mixing |

| Heating Zones | 4 zones with PID control | Precise temperature management |

| Motor Power | 15 kW | Reliable performance with low energy consumption |

| Max Width of Curtain | 2000 mm | Flexibility for various door sizes |

This machine is tailored for a wide range of users, from industrial manufacturers and contractors to startups entering the plastic products industry. Common applications include creating door curtains for cold storage facilities, factories, supermarkets, and greenhouses. By investing in this technology, businesses can reduce operational costs, improve product consistency, and respond quickly to market demands. The ease of use also makes it accessible for operators with varying skill levels, fostering growth and innovation within teams.

Using the PVC Door Curtain Extrusion Machine brings a sense of confidence and control. No longer will you worry about frequent breakdowns or subpar products. Instead, experience the satisfaction of delivering items that enhance safety and efficiency for end-users. This machine addresses critical issues like energy loss in buildings and contamination risks, empowering you to contribute positively to your clients' environments. The ripple effect includes higher customer satisfaction and repeat business, building a reputation for reliability.

Compared to conventional extruders, our model integrates automated calibration and real-time monitoring, reducing human error. The use of corrosion-resistant alloys extends the machine’s lifespan, while modular components simplify maintenance. Qingdao Eaststar Plastic Machinery Co., Ltd. also offers customizable configurations, allowing adaptations for specific materials or output requirements. These elements combine to provide a competitive edge, ensuring your investment yields long-term dividends.

What is the typical lead time for delivery and installation?

Delivery usually takes 2-4 weeks after order confirmation, depending on location. Installation services are available, with on-site support to ensure proper setup and operator training.

Can the machine handle recycled PVC materials?

Yes, it is compatible with both virgin and recycled PVC, though we recommend pre-drying recycled materials to maintain optimal extrusion quality and prevent defects.

How energy-efficient is this extrusion machine?

It incorporates energy-saving motors and heating systems, reducing power consumption by up to 20% compared to older models, which helps lower operational costs over time.

Is technical support available after purchase?

Absolutely. Qingdao Eaststar Plastic Machinery Co., Ltd. provides 24/7 remote assistance, along with optional maintenance contracts and spare parts supply to ensure uninterrupted production.

What safety features are included?

The machine comes with emergency stop buttons, overheating protection, and insulated electrical components to safeguard operators and prevent accidents during use.

Can I customize the output width and thickness?

Yes, adjustable dies and control settings allow for customization within the specified range, enabling you to produce curtains tailored to specific customer requirements.